- Home

- Alloy Materials

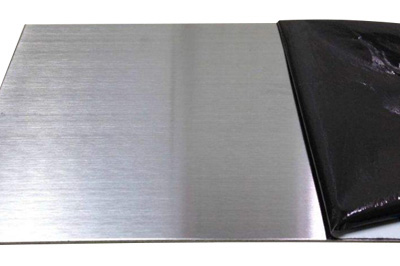

- Nickel-based Alloy

Nickel-based alloy is a type of heating resistant austenite alloy material. Compared to microscale tungsten (W), a material known for its hardness and durability, nickel-based alloy has higher hardness. At the same time, it has relatively high nickel content, meaning higher temperatures are needed for processing.

-

- Hastelloy B/B-2 (UNS N1001/N10665)

Fe and Cr are used minimally, resisting B phrase NI14MO to produce

Great resistance to stress corrosion cracking and pitting

-

- Hastelloy B-3 (UNS N10675)

Hastelloy B-3 is a nickel-molybdenum alloy giving it excellent resistance to pitting, corrosion, and stress-corrosion cracking

It can also endure sulfuric, acetic, formic, and phosphoric acids, as well as other non-oxidizing media.

-

- Hastelloy C-22 (UNS N06022)

Hastelloy C-22 is an alloy that contains nickel, chromium, molybdenum and tungsten, which makes the alloy resistant to corrosion in stagnant or flowing seawater

Outstanding resistance to both reducing and oxidizing media

-

- Hastelloy C-4 (UNS N06455) Hastelloy C-4 maintains outstanding stability and resilience to high temperatures to resist stress corrosion cracking. Adaptable to corrosive substances like mineral acid, chloride medium, acetic acid, acetic anhydride, sea water, etc.

-

- Hastelloy S (UNS N06635) This alloy is a high-temperature, nickel-based alloy. Hastelloy S alloy is resistant to oxidation at 1095°C and delivers excellent thermal stability. Furthermore, this alloy can regain its ductility and strength after aging in a temperature range of 427 to 871°C.

-

- Hastelloy C276 (UNS N10276)

Adding tungsten to the alloy gives it outstanding corrosion resistance even when applied in severe environments

Resistant to pitting and crevice corrosion in reducing environments

-

- Hastelloy C-2000 (UNS N06200/NICR23M016CU)

Hastelloy C-2000 is a material specially designed for resistance to an extensive range of corrosive chemicals including sulfuric, hydrochloric, and hydrofluoric acids over a large temperature range.

Resistance to stress corrosion cracking

-

- Hastelloy G-30 (UNS N06030) HASTELLOY G-30 is an enhanced version of nickel-chromium-iron molybdenum-copper alloy G-3 and contains a high amount of Cr. This alloy has greater corrosion resistance compared to other nickel-based alloys, making it suitable for use in applications where it may be exposed to commercial phosphoric acids and environments with highly oxidizing acids as well.

-

- Hastelloy X (UNS N06002) HASTELLOY X is a nickel- chromium- iron- molybdenum alloy with great resistance to oxidation under 1200℃. This alloy has outstanding cold and hot forming capabilities, and it should be heated to a starting temperature of 1175°C prior to processing.

-

- Hastelloy N (UNS N10003) HASTELLOY N boasts high creep and oxidation resistance. It can also endure high temperatures and maintain good condition under severe mechanical stress. Between the temperatures of 705-870℃, the alloy is resistant to fluoride salts and oxidation.

-

- Haynes 230 (UNS N06230) HAYNES 230 is a useful material that features high-temperature strength and outstanding resistance to oxidizing environments up to 1149°C for long time exposure. It is easily fabricated and has very good forming and welding characteristics.

-

- Haynes 556 (UNS R30556) Haynes 556 has the best combination of strength, resistance to high-temperature corrosion, and also has outstanding fabrication capabilities. It is an excellent welding material for nickel-chromium alloys and iron-nickel-chromium materials

-

- Haynes 188 (UNS R30188) This is a nickel-based alloy that offers high strength at high temperatures as well as oxidation resistance. It also provides resistance to sulfidation and enables easy processing.

-

- Inconel 600 (UNS N06600)

Inconel 600 is a nickel-based alloy that features resistance to corrosion and high temperature. It can be formed easily.

Virtually immune to chlorine ion stress corrosion cracking

-

- Inconel 601 (UNS N06601)

This alloy is resistant to high temperature oxidation, avoiding oxidation up to 1204℃.

Inconel 601 alloy has good high temperature strength, and retains its ductility even after long periods of exposure to heat.

-

- Inconel 625 (UNS N06625/W.NR.2.4856)

Inconel 625 is a corrosion and oxidation resistant nickel-based alloy that provides high strength and withstands aqueous environments.

Inconel 625 has excellent fatigue strength and stress-corrosion cracking resistance when exposed to chloride ions

-

- Inconel 718 (UNS N07718)

Under 700℃ it has exceedingly high tensile strength, anti-fatigue performance, and demonstrates resistance to creep-rupture

Highly antioxidant when temperatures reach 1000℃

-

- Inconel X-750 (UNS N07750/GH4145) UNS N07750 has good anti-corrosion quality and resistance to oxidants under 980℃. It has relatively high strength under 800℃, and also has excellent mechanical properties down to cryogenic temperatures

-

- Carpenter 20 (UNS N08020/NS143) Carpenter 20 alloy demonstrates a great deal of resistance to acid, particularly sulfuric acid. This acid can cause general corrosion, pitting, and crevice corrosion in other materials. The great mechanical properties and relatively easy fabrication make it suitable for application in a variety of industries.

-

- Incoloy 800/800H/800HT (UNS N08800/ N08810/ N08811)

Outstanding corrosion resistance, heat resistance, high strength

It has good mechanical properties

At elevated temperatures it offers resistance to oxidation

-

- Incoloy 825 (UNS N08825/NS142)

Excellent resistance to oxidizing acids

Resistance to stress-corrosion cracking

Very resistant to sulfuric and phosphoric acids

-

- Incoloy 926 (UNS N08926)

Outstanding resistance to chloride-induced stress corrosion

Very good corrosion resistance when in contact with oxidizing and reducing media

-

- Incoloy 925 (UNS N09925) Incoloy 925 has excellent mechanical strength and a wide range of anti-corrosion abilities as well as resistance to pitting and crevice corrosion.

-

- Inconel 617 (UNS N06617)

Highly resistant to oxidation and carburization

Maintains stable mechanical properties under 1100℃

This alloy can be easily fabricated.

-

- Monel 400 (UNS N04400)

Monel 400 alloy is resistant to sea water and steam at high temperatures

Resistant to salt and caustic solutions

Resistance to stress-corrosion cracking in most freshwater environments

-

- Monel K500 (UNS N05500)

The Monel K500 alloy combines the excellent corrosion resistance of MONEL 400 with greater strength and hardness.

It has a tendency toward stress-corrosion cracking in some environments

-

- Alloy 4J29

This is an iron-nickel-cobalt alloy, the coefficient of expansion of 4J29 alloy is close to borosilicate glass within the temperature range of -80~450℃,

It has a high Curie temperature and maintains stability at low temperatures.

-

- Alloy 4J36

4J36 alloy is an iron-nickel alloy with 35%~37% nickel content.

4J36 alloy has a low coefficient of expansion from cryogenic temperatures to about 500℃

-

- Magnetic Alloy 1J22 1J22 is known as soft magnetic alloy with high saturation magnetization(2.4T) and high Curie temperature (980℃), because of the features above, when us it to produce motors, it will decrease the volume of motor with no power lose.